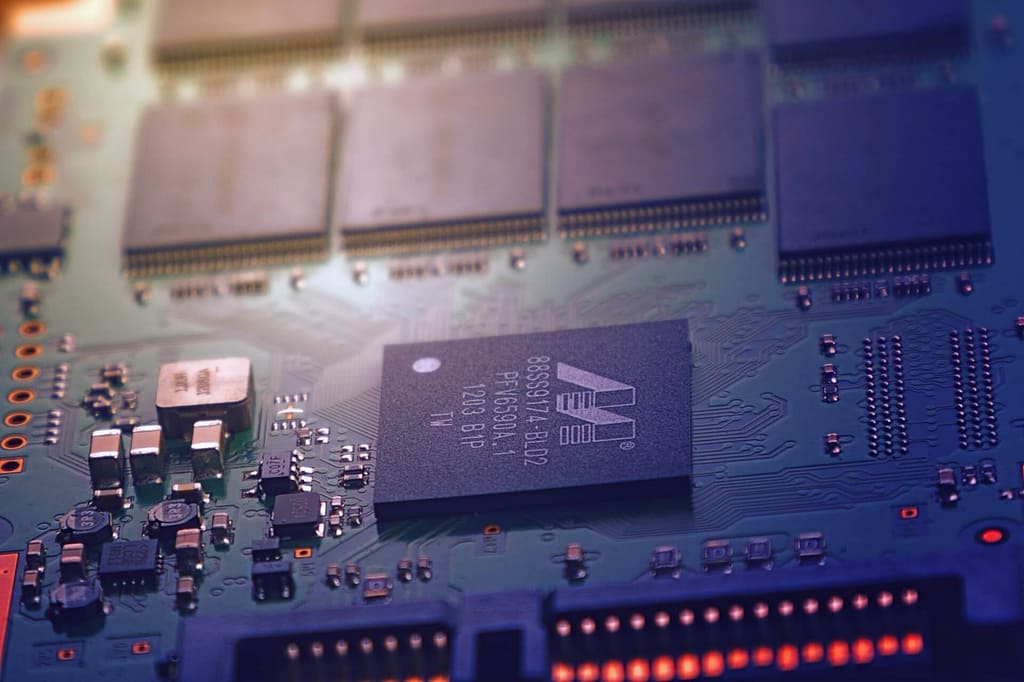

our pcb recovery plant

Our pilot plant for PCB metal recovery has been developed by Smart Creative Technologies in conjunction with ITRI Ltd, a leading international metals research institute. Our environmentally friendly process is simple, cost-effective and can be used to treat any grade of scrap boards. Our process uses ferric chloride (FeCl3) and ultrasonic agitation to generate a cleaner, richer mixed metal ‘cake’ that greatly simplifies the refining of contained metals. All solders (Example: tin, lead, copper & silver) are dissolved, which releases small electronic components, undamaged, that can be treated separately to recover additional metals and polymers.

The only current commercial approach for recycling waste PCB’s is smelting the boards in large centralised facilities used for the extraction of non-ferrous base metals.

Smelting PCB’s has many disadvantages such as: