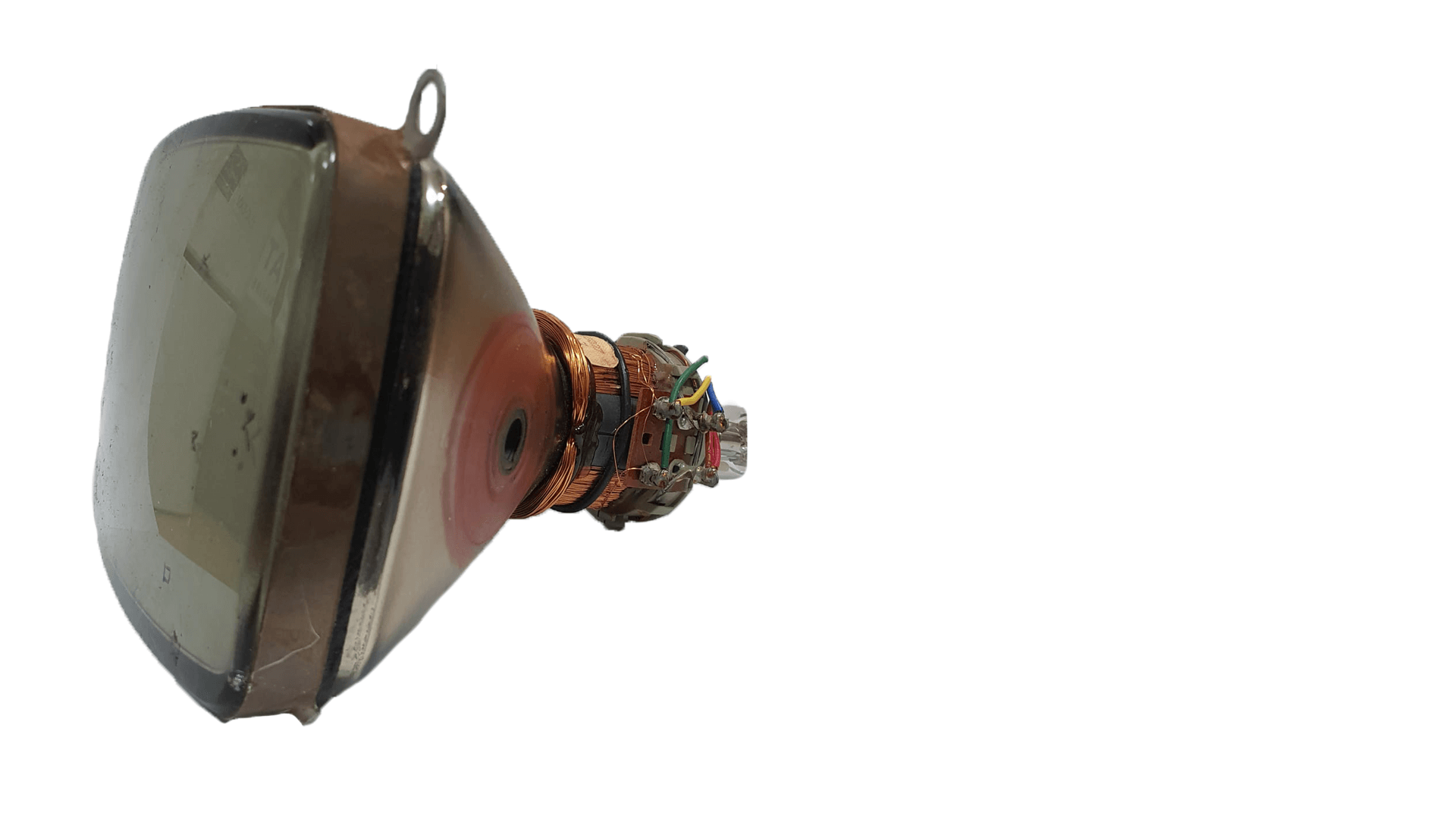

Our crt lead recovery process

Smart Creative Technologies patented process can also be used for the recovery of lead from CRT Leaded Glass screens, the process is able to recover 99.9% of lead from CRT glass. A valuable, clean by-product sodium silicate (liquid glass) is also produced, which has many industrial uses, instead of toxic slag. Globally there are approximately 1.9 billion CRTs still in use, which equates to around 38 million tonnes of leaded glass. European legislation classifies television and computer screens as Hazardous Waste and they cannot be disposed of in ordinary landfills under the Landfill Directive (UK). There are currently two commercial solutions for CRT waste that are utilised in the WEEE recovery marketplace. The first is to export the leaded glass to make new screens.

Long term issues with this method: